Phone Number

Email Address

Office Address

Model series SWF, SWP, SWF-HE, SWP-HE

FUNKE is a leader in the development and production of quality heat exchangers with a heat transfer area of up to 2 400 m². The range of products comprises shell-and-tube heat exchangers, bolted and brazed plate heat exchangers as well as oil / air cooling units and electrical oil pre-heaters. Thus, as one of the few producers worldwide, FUNKE offers solutions with optimum thermodynamic designs for different industries and virtually all applications.

FUNKE focuses on customer orientation, highest quality standards, flexibility and advisory skills – important benefits na company of just the right size is able to offer.

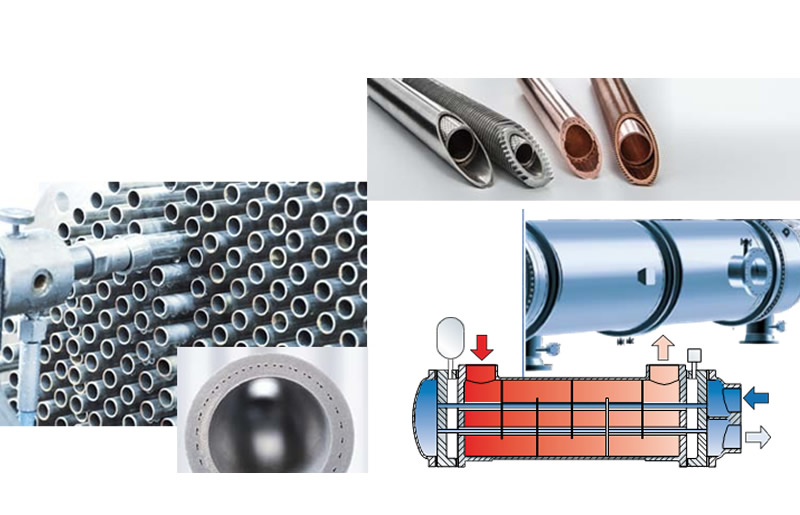

Safety heat exchangers are designed as three chamber devices with straight internal tubes and fixed (F) or removable (P) tube bundle. In each individual internal tube of the tube bundle a further smaller internal tube is installed. These concentric internal tube pairs form radial gaps which are interconnected by the design of the double tubesheets and thus produce the enclosed safety space. A mixing of the flowing operating media is prevented in this way.

This sealed safety space is filled with a special barrier fluid. It is responsible for the heat transfer in the radial gap and functions as a transmitter in the leak monitoring system. The safety area is sealed off and permanently monitored for pressure changes (pressure monitoring P).

In the case of a leakage of the shell or tube sides, the correspond- ing pressure change within the safety space will be detected by the pressure control device and signalled accordingly. The safety area is also equipped with an expansion tank (V) which prevents false alarms due to thermal volume or pressure changes.

FUNKE’s new SWF-HE and SWP-HE ranges meet the increas- ingly stringent requirements for systems based on this safety principle.

In conventional technical solutions with double tubes, the outer tube has a relatively rough structure on its interior. FUNKE, however, shifts the structure to the outside of the inner tube and uses a finer structure in a pyramid shape.

The advantages of moving the structure to the inner tube are

• Contact area between inner and outer tube of a double tube increased by up to 80%

• Optimized distribution of safety channels

• Heat transfer with or without transmitter fluid in the safety area

• Optimum tube / tube sheet connection by rolling in with groove and / or welding

• Crevice corrosion prevented by applying the inner tubes after tubes are welded in

• Compact sizes and reduced weight

In case of leakage the application of FUNKE safety shell-an-tube heat exchangers prevents from transferring pressure and tempe- rature to the other side and avoids other undesirable consequen- ces such as

• A chemical reaction when the media mix together

• Possible damage to the low pressure side of the heat exchangers

• Damage to downstream system components from mixed media or increased temperatures and pressure

• Hazards for human beings and the environment

• Removing, replacing and disposing of mixed media

• Downtime due to the need of purchase a replacement or make repairs

The FUNKE safety shell-and-tube heat exchangers with expan- ded double pipes are mainly used in the chemical industry, phar- maceutical technology, solar industries, natural gas pre-heating and transformer oil cooling (according to DIN EN 501216-9).