Phone Number

Email Address

Office Address

Universal solutions for industrial and domestic applications

FUNKE is a leader in the development and production of quality heat exchangers with a heat transfer area of up to 2 400 m². The range of products comprises shell-and-tube heat exchangers, bolted and brazed plate heat exchangers as well as oil / air cooling units and electrical oil pre-heaters. Thus, as one of the few producers worldwide, FUNKE offers solutions with optimum thermodynamic designs for different industries and virtually all applications.

FUNKE focuses on customer orientation, highest quality standards, flexibility and advisory skills – important benefits a company of just the right size is able to offer.

With a large range of standard- and special designs the FUNKE brazed plate heat exchangers can cover manifold applications in different industrial areas and domestic applications.

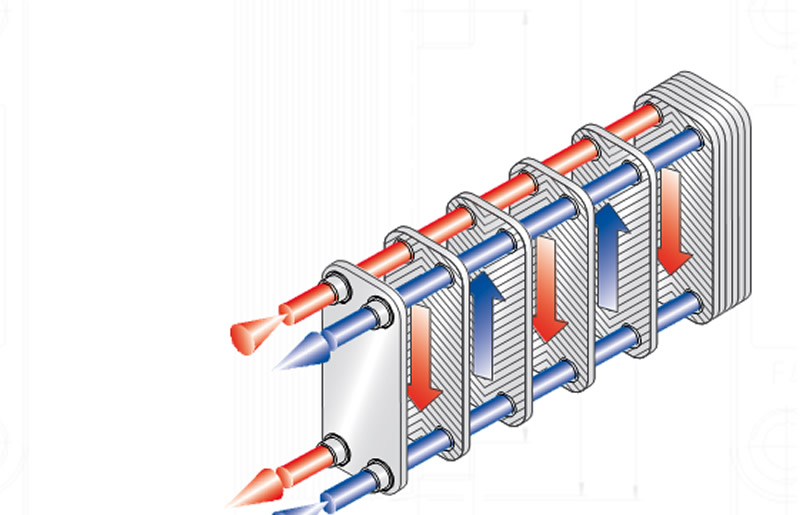

FUNKE brazed plate heat exchangers are made of cor- rugated stainless steel plates. The plates are assembled in a 180° angle to each other. Depending on the require- ments of the application, the plates are vacuum brazed to a pressure-resistant unit using either copper or nickel. This results in separate flow gaps with counter-flow of the media involved in the heat exchange (standard).

The series GPL, GPLK und TPL provide for a well balanced ratio of high heat transfer rates with low pressure losses. The thermodynamically optimized corrugation of the em- bossed plates and the inserted turbulators (TPL) allow for high turbulent flow even at low volumetric flow rates. This allows for efficient use of the heat exchange area available and leads to a perfectly optimized heat transfer. The high turbulent flow also results in an efficient self-cleaning effect, which greatly reduces maintenance and time-out. FUNKE brazed plate heat exchangers have a compact design and are used for high pressures and temperatures.

Typical applications for brazed plate heat exchangers are heating, cooling, condensing

• System separation

• Heat extraction and heat recovery in domestic and process technology

• Refrigeration engineering

• Mechanical engineering

• Oil cooling

• Hot water / Process water

• Heating engineering (solar thermal systems, central heating, floor heating)

• Evaporation / Condensing in cooling systems

• Air drying

• Hydraulic oil cooling

• Cooling of machines and motors

• Mold machine temperature control

• Economizing

Copper brazed plate heat exchangers GPLK should not be used for the following media:

• Seawater

• Ammonia

• Deionates

• Silicone oils

• high chloride media

For applications with

• Ammonia

• Deionates

• Silicone oils

the nickel brazed plate heat exchangers NPL are recom- mended.

Copper brazed plate heat exchangers are mainly used for media such as

• Oil and oil containing fluids

• Glycol mixtures

• Alcohols

• Refrigerants

• Gas / Air

• Water

• many more (according to media properties and its viscosity)

.