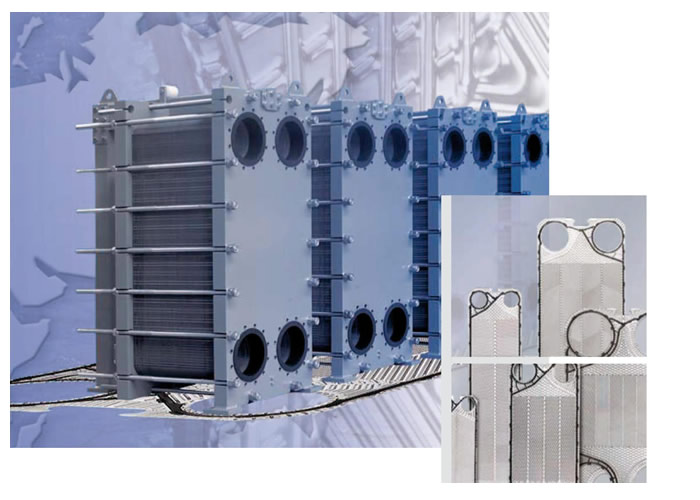

Plate Heat Exchangers Series FP

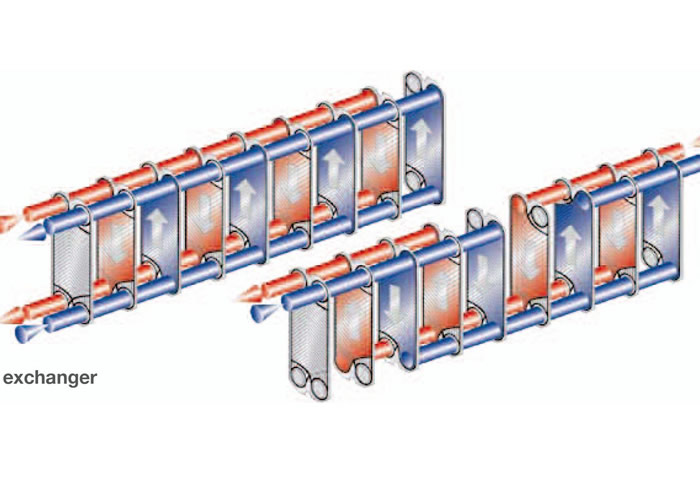

With the sophisticated “Off-Set” profile our customers benefit from an additional tool for providing cost-effective PHE solutions.

An oil cooler, for example, is significantly smaller and cheaper if the volume flow on the cooling water side can be much larger.

Therefore, up to 17 per cent less exchange surface is required compared to conventional symmetrical plates. The configuration of the plate pack is always calculated using state-of-the-art design software, whether symmetrical or asymmetrical. So,

FUNKE always aims to find the most efficient and cost effective solution for the customer.

Always the right plate for your requirements

“Off-Set”- embossing for highest efficiency All plate heat exchangers look very similar at first glance. But the difference and the secret of efficient heat transfer cannot be seen from the outside – it is the wave pattern.

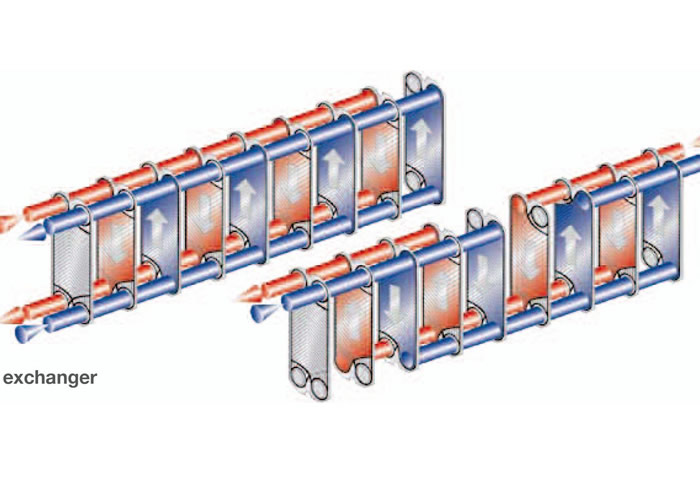

Its performance depends on many factors, including size and number of plates. Altogether, these factors determine the size of the plate heat exchangers and the operating costs.

A crucial factor e.g. is that plates with different plate cor- rugation angles (in relation to the flow direction) can be combined. Obtuse corrugation angles result in longer ther- mal paths (H) and higher heat transfer rates but also lead to higher pressure drops. Acute corrugation (L) angles are chosen if the pressure drop must be kept low.