About M&J Valve

As a Celeros Flow Technology brand, M&J Valve is a key technology partner to companies across the globe that are involved in the storage, transportation, production or processing of gases and liquids. Founded in 1962, the M&J brand has an established history of product innovation and provides a wide variety of flow control solutions to the liquid, geothermal and gas markets.

The extensive M&J range includes control valves, gate valves, check valves, diverter valves and surge valves, plus flow loops for valve testing purposes. M&J valves make use of an array of different shut-off mechanisms (slab, piston, swing, rotary and axial) to satisfy a wide range of application characteristics. They are suitable for incorporation into overland and subsea pipelines, storage facilities, offshore platforms and pumping stations.

Thanks to high grade engineering and quality of manufacture, M&J valves can deal with a broad range of different pressure conditions and a large number of cycles, as well as offering ease of use, ongoing reliable operation and prolonged seal life. Comprehensive aftermarket services, accessible through the global network of Celeros Flow Technology service centers, help customers to maintain lifecycle performance and optimize return on investment.

A Diverter Valve System by Flow Measurement and Valve Specialists

The 4-Way Diverter Valve and its operating mechanism (manual, electric motor or hydraulic actuator) are designed to operate as a system ideally suited for meter proving, which requires:

Frequent operation (cycling). A diverter valve often is cycled 300 times per day compared to once per

week for ordinary valves and only twice per year for many valves.

Rapid operation. In bi-directional meter proving the diverter valve must cycle in 4 to 10 seconds compared to the 30 to 60 seconds cycling time for

ordinary valves.

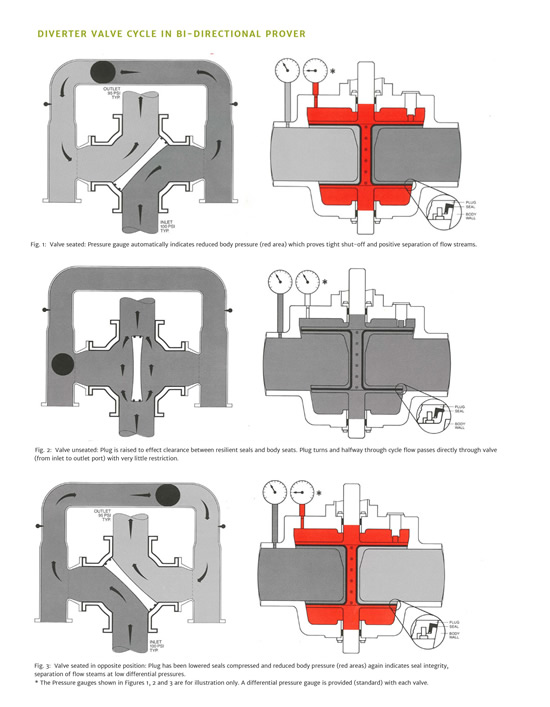

No Leakage. Proof of no leakage during each prover run is required by the API Liquid Measurement Manual 2531. The 4-Way Diverter Valve with its automatic pressure seating method indicates the seal condition every time the valve seats. On automated systems, prover runs are canceled if the seal condition is not acceptable.